Overview

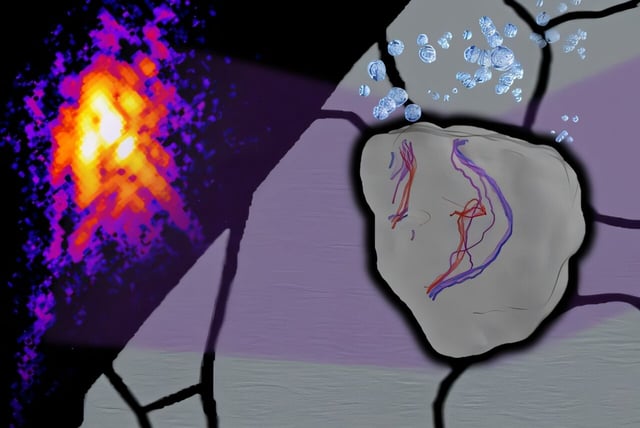

- Researchers directly tracked how hydrogen changed internal defects in stainless steel using Bragg Coherent Diffraction Imaging in a live 3D experiment.

- The team monitored a single grain about 700 nanometers across for roughly 12 hours as hydrogen was introduced, reconstructing its evolving internal structure.

- Hydrogen made dislocations unexpectedly mobile, with faults moving and reshaping even without additional external stress.

- The experiment observed out-of-plane dislocation climb at room temperature and a measurable reduction of surrounding strain fields, providing direct 3D evidence of hydrogen elastic shielding.

- The peer-reviewed study, published September 9, 2025 in Advanced Materials by collaborators from Oxford, Brookhaven, Argonne, and UCL, will inform multi-scale simulations and guide follow-on tests toward industry-relevant conditions.