Overview

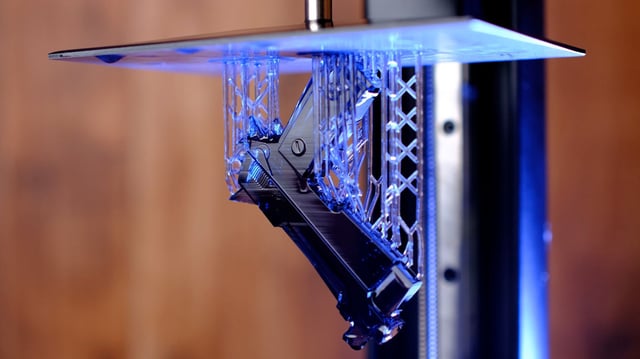

- The Nature Materials paper published June 30 details a custom resin and dual-light system that uses violet and ultraviolet wavelengths to cure soft and rigid regions in one continuous print.

- Scientists embedded a molecule with two reactive groups to enable chemical ‘communication’ at the interface, producing a strong, gradual transition without weak points.

- The team printed a working knee joint with elastic ligaments and rigid bones alongside a stretchable electronic prototype featuring a bendable gold wire and stiff supports.

- Compared with prior multimaterial approaches, the process delivers faster throughput, finer resolution and stronger interlayer adhesion using a simple, affordable printer setup.

- The accessible platform is poised for rapid adoption in research labs, hospitals and educational institutions and could accelerate next-generation prosthetics, medical devices and soft robots.