Overview

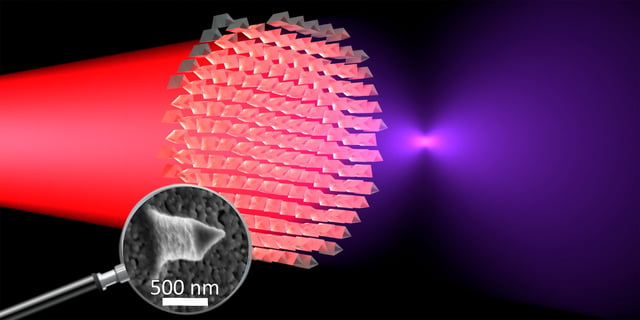

- Researchers demonstrated frequency-doubling of 800 nm infrared beams into 400 nm visible violet light using ultra-thin metasurfaces on lithium niobate.

- The fabrication protocol employs nanoimprinting of a liquid precursor followed by a 600 °C heat treatment to crystallize nanostructures for light conversion.

- Nonlinear optical interactions in the metalenses remain wavelength-agile, allowing flexible frequency conversion across diverse input bands.

- Reusable inverse molds enable a scalable manufacturing route that cuts costs and supports large-volume output of the flat lenses.

- Potential applications range from counterfeit-proof security features and infrared visualization in standard cameras to enhanced telecommunications and sensing devices.