Overview

- ATSP reinforced with carbon fibers achieved specific strengths several times that of steel while remaining lighter than aluminum.

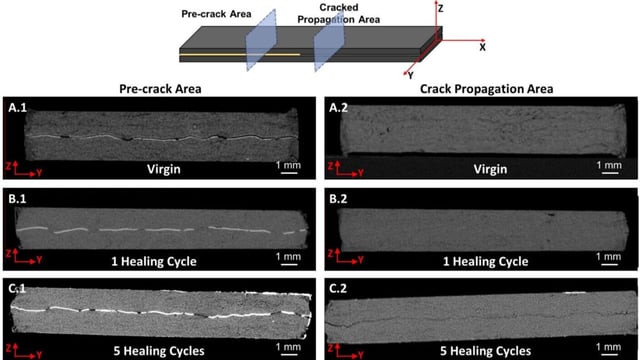

- Heating to about 160 °C triggered self-healing that restored nearly full strength after two cycles and about 80 percent efficiency by the fifth cycle under 280 °C exposures.

- Hundreds of combined stress-heating cycles caused no catastrophic failures and in some tests improved durability during the healing process.

- The material’s adaptive vitrimer chemistry maintained integrity across successive reshaping and recycling cycles, suggesting a lower-waste alternative to traditional plastics.

- Researchers highlight near-term prospects for on-demand repair in defense, aerospace and automotive components but note that scaling production and addressing localized manufacturing defects remain hurdles.