Overview

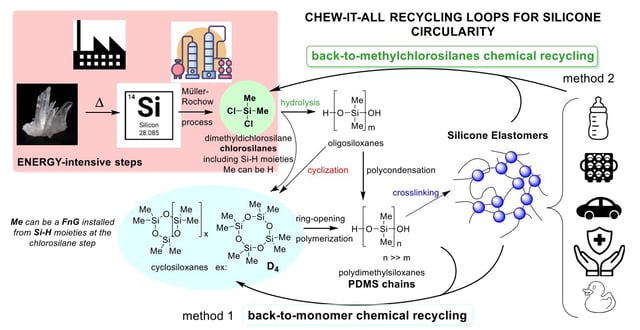

- A new chemical recycling method uses gallium catalysis and boron trichloride to break down silicone polymers into pristine chlorosilane monomers.

- The process operates at 40 °C with yields approaching 97%, significantly reducing energy consumption and CO₂ emissions compared to traditional silicone manufacturing.

- Unlike existing mechanical recycling, this method allows any type of silicone waste to be recycled without degrading material quality, enabling infinite reuse cycles.

- The recycled chlorosilane monomers match the purity of virgin materials, ensuring performance in applications like electronics and medical devices.

- Researchers are collaborating with industrial partners to optimize the process for large-scale deployment and expand its application to other silicone processing stages.