Overview

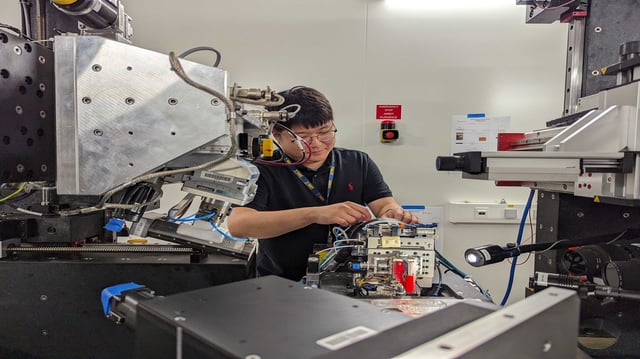

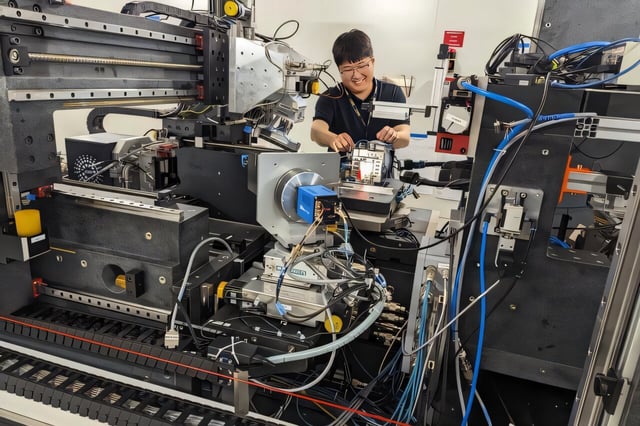

- University of Michigan researchers leveraged dark-field X-ray microscopy at the European Synchrotron Radiation Facility to obtain 3D images of deformation twins in magnesium alloy crystals without damaging the samples.

- Experiments revealed that all three types of deformation twins nucleate at triple junctions of crystal grains and that defect clusters consistently form where twins intersect adjacent crystals.

- The team applied tensile loads of 0.6, 30 and 45 megapascals—mirroring typical automotive forces—and captured sequential images to track twin growth and defect emergence.

- Funded by the U.S. Department of Energy and published in Science, the results offer a blueprint for designing magnesium alloys that balance ductility and stability for lighter, stronger vehicle components.

- Researchers are preparing follow-up experiments to record these microstructural changes in real time and further optimize alloy performance under mechanical stress.