Overview

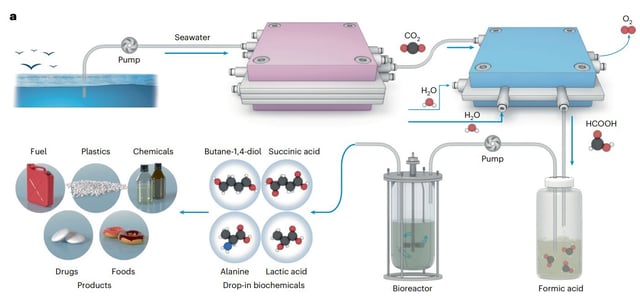

- Researchers in China report an integrated setup that captures dissolved CO2 from seawater, concentrates it via a hollow‑fiber membrane, converts it to formic acid with a bismuth‑based MOF catalyst, then ferments it with engineered Vibrio natriegens to make succinic acid.

- In continuous tests the direct ocean capture reactor operated for about 536 hours with roughly 70% capture efficiency and an energy use near 3 kWh per kilogram of CO2.

- The team estimates a capture cost of about $229.9 per metric ton, based on lab operation, positioning the approach as potentially competitive with current carbon‑capture technologies.

- Using natural Shenzhen Bay seawater, the system produced around 6.54 liters of CO2 from 177 liters of intake and neutralized processed water with internally generated sodium hydroxide for discharge back to the ocean.

- The authors emphasize proof‑of‑concept status with succinic acid titers up to 1.37 g/L and suggest the platform could be adapted to other chemicals, as industry players note competing DOC claims and the need for scale‑up, durability data, and full life‑cycle accounting.