Overview

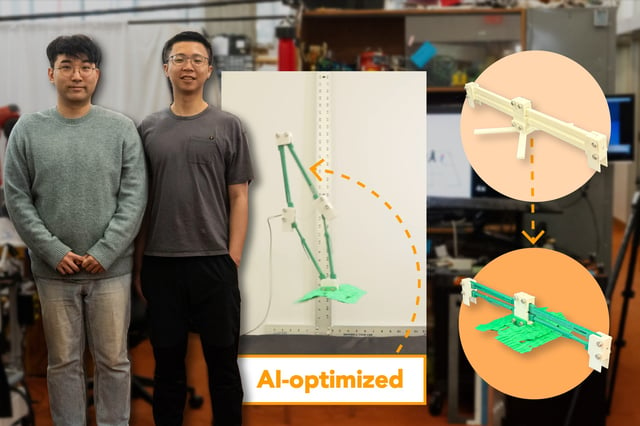

- The diffusion-based framework modifies user-defined 3D parts through five rounds of 500 simulated variants to converge on energy-efficient designs before fabrication.

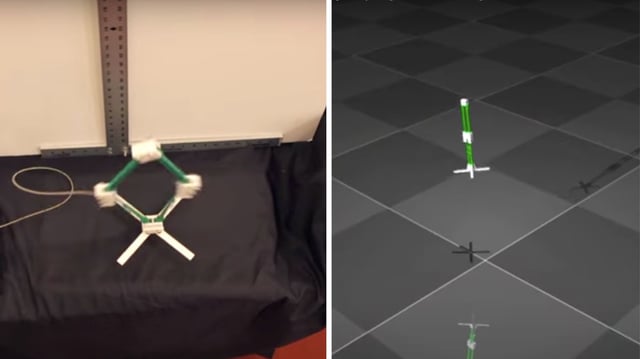

- A 3D-printed prototype vaulted two feet tall and achieved markedly fewer falls than its human-designed counterpart in ICRA 2025 demonstrations.

- AI-model outputs curved, drumstick-like linkages that store jump energy more effectively than traditional straight connectors.

- Next steps include incorporating natural language design prompts, exploring lighter composite materials and adding actuators for directional control.

- The project is driven by MIT CSAIL under Daniela Rus and supported by NSF’s Emerging Frontiers program, the Singapore-MIT Alliance and GIST.