Overview

- MIT researchers have developed a new additive manufacturing technique called Liquid Metal Printing (LMP) that can rapidly 3D print large-scale parts like table legs and chair frames in minutes.

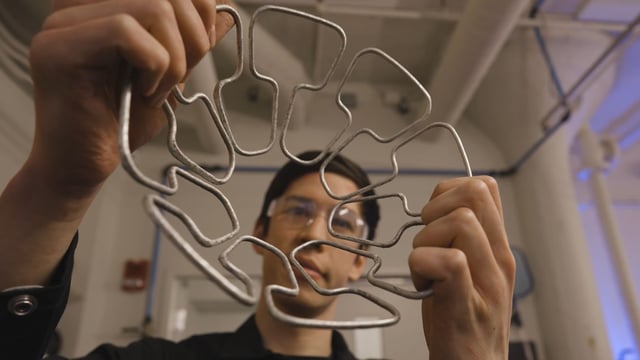

- LMP involves depositing molten aluminum along a predefined path into a bed of tiny glass beads, which quickly harden into a 3D structure.

- The technique is at least 10 times faster than comparable metal additive manufacturing processes, but sacrifices resolution for speed and scale.

- Parts produced with LMP would be suitable for some applications in architecture, construction, and industrial design, where components of larger structures often don’t require extremely fine details.

- The researchers aim to refine the machine further to ensure consistent heating in the nozzle to prevent material from sticking and achieve better control over the flow of molten material.