Overview

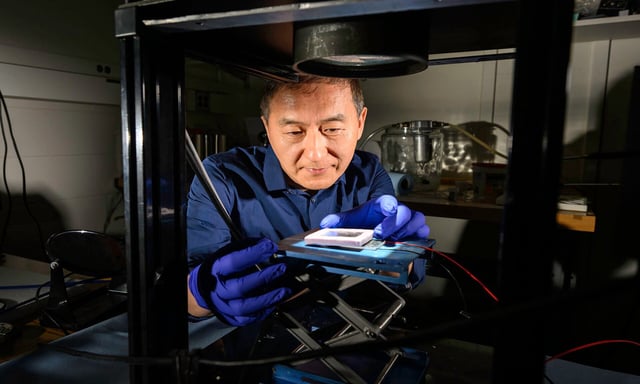

- The University of Rochester team reported peer-reviewed results showing that a lab-scale STEG prototype delivers roughly 15× more power than previous designs by optimizing its hot and cold sides.

- Researchers applied femtosecond-laser etching to tungsten to create a 'black metal' absorber and added a plastic 'mini-greenhouse' layer to trap heat on the hot side.

- Laser-textured aluminum heat sinks doubled cooling performance and boosted the temperature differential driving the Seebeck effect.

- Prototype devices successfully powered LEDs in lab tests, pointing to potential uses in IoT sensors, wearable gadgets, and off-grid renewable systems.

- Additional scaling, field validation, durability assessment, and cost analysis are required before the technology can be commercialized.