Overview

- KIOST’s results were peer reviewed in Scientific Reports on July 30, 2025, in a paper titled “Prototype ultrasonic desalination instrument and its performance test” (DOI: 10.1038/s41598-025-12764-3).

- Conventional washing typically uses about four tons of water to treat one ton of sand, while the ultrasonic approach reduces both water consumption and processing time.

- The instrument leverages cavitation, strong particle clearance from bubble collapse, enhanced penetration force, and non-contact ultrasonic cleaning.

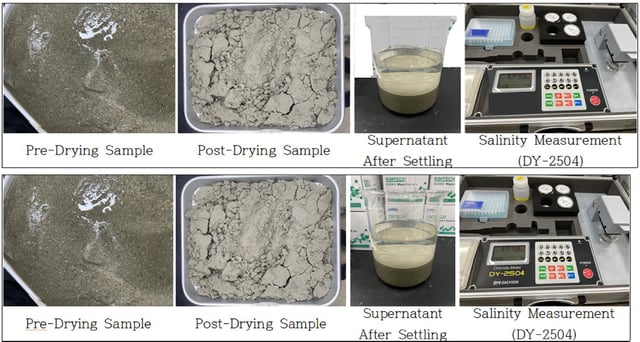

- Experiments defined practical settings for compliance, specifying a 1:2 sand-to-water ratio with ultrasonic power of at least 300W for three minutes to reach ≤0.04% salinity.

- KIOST describes the system as a prototype and signals plans to scale the technology for faster, larger-volume processing as sea sand increasingly substitutes for restricted river sand.