Overview

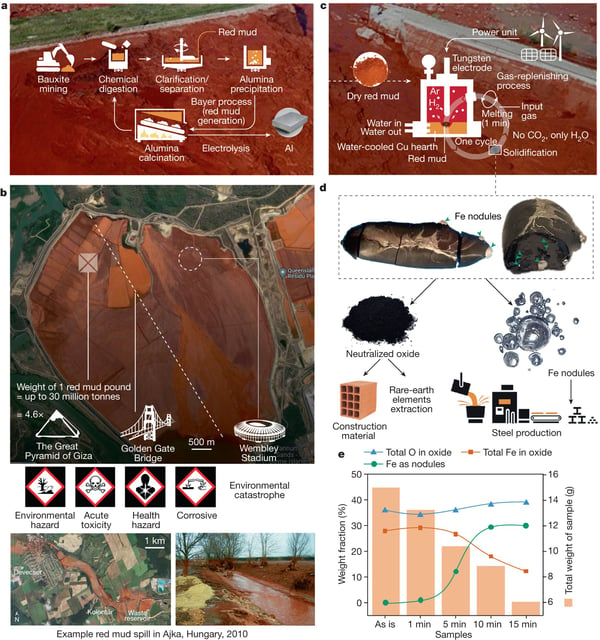

- German metallurgists have developed a method to extract iron from aluminum production waste, known as red mud, which is highly alkaline and contains a high concentration of heavy metals.

- Approximately 180 million metric tons of red mud are produced annually, with current global reservoirs holding around 4 billion metric tons of the hazardous material.

- The new method involves exposing the red mud to hydrogen plasma, which converts the waste into a viscous melt, then into liquid iron and steam. The liquid iron is then removed.

- The process has been found to be economically viable when scaled up, although a pilot-scale facility is required to verify these projections.

- The iron extracted from the red mud could be used to make steel, potentially reducing the environmental impact of both aluminum and steel production.