Overview

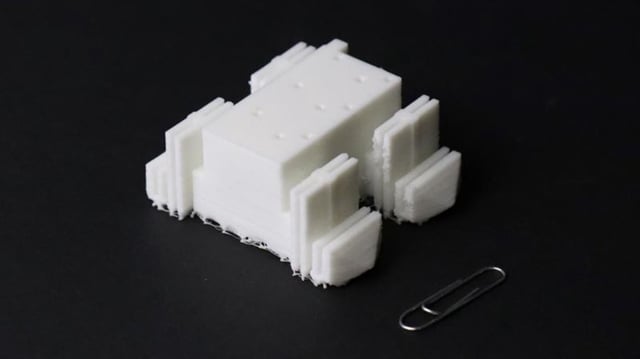

- Flexible thermoplastic polyurethane filament and an inverted printing method ensure precise layer bonding for durable soft robot bodies.

- A pneumatic ring oscillator delivers a pulsating 2.25-bar air current through internal channels to trigger the quadrupeds’ walking motion without electronics.

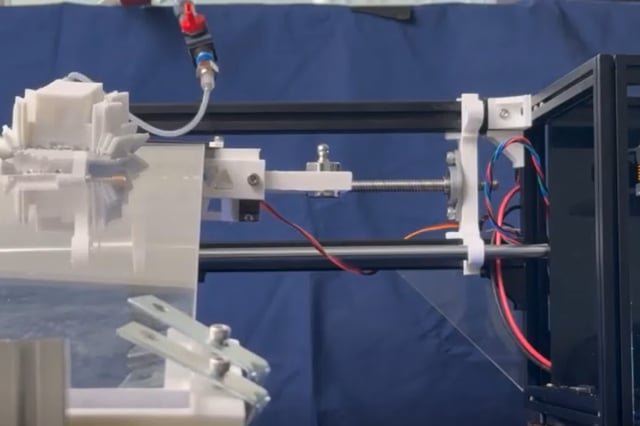

- The desktop Flex Printer can be assembled by beginners in a matter of days using common components costing less than £400 ($539).

- All hardware schematics and control software have been released under an open-source license to foster collaboration and further innovation.

- Instant-print soft robots could expand applications in nuclear decommissioning, minimally invasive surgery, rehabilitation and space exploration.