Overview

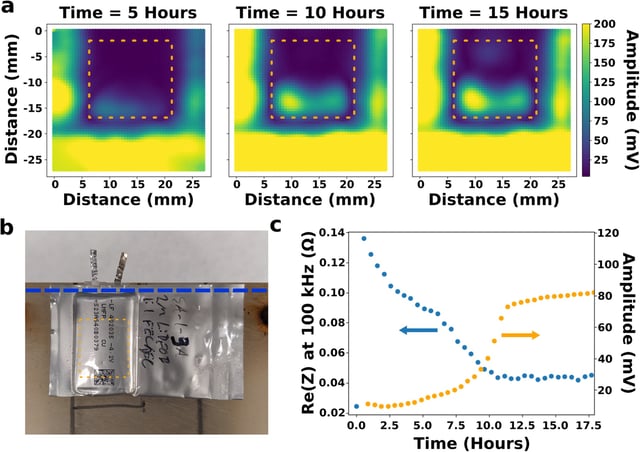

- The benchtop system uses low-energy sound waves to detect structural anomalies such as gas pockets, cracks and dry spots without interrupting battery operation.

- Ultrasonic imaging delivers real-time diagnostics faster and at lower cost than conventional X-ray inspections, offering manufacturers scalable quality control.

- Deployment at SES AI’s research facility validated instant feedback during cell design and testing, accelerating engineering adjustments.

- An open-source software interface accompanies the instrument to streamline data analysis and encourage widespread adoption by battery engineers.

- Ongoing development focuses on full-cell and electrode 3D imaging to enhance detection of internal flaws and prevent thermal runaway.