Overview

- Carbon-fiber–reinforced ATSP composites deliver strength multiple times that of steel and weigh less than aluminum, withstanding thermal cycles up to 280 °C.

- Thermally activated bond exchanges around identified glass transition and vitrification temperatures (~160 °C to 280 °C) enable on-demand self-healing and shape recovery.

- Testing showed near-full strength recovery after two damage–healing cycles with efficiency dropping to about 80% by the fifth cycle due to accumulating mechanical fatigue.

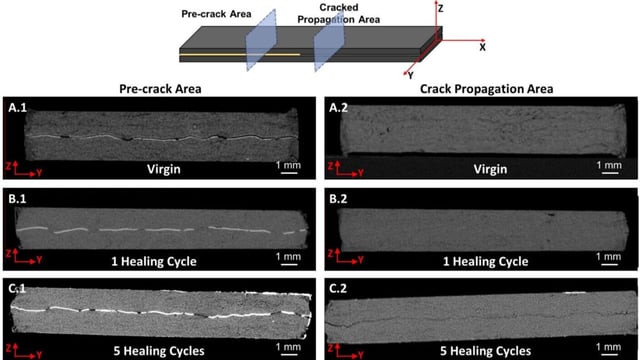

- High-resolution imaging confirmed that healed composites closely match their original structure and maintain chemical stability without evidence of thermal degradation.

- Backed by the U.S. Air Force Office of Scientific Research and industry partner ATSP Innovations, researchers highlight scale-up challenges as fatigue and manufacturing defects must be addressed for aerospace and automotive qualification.