Overview

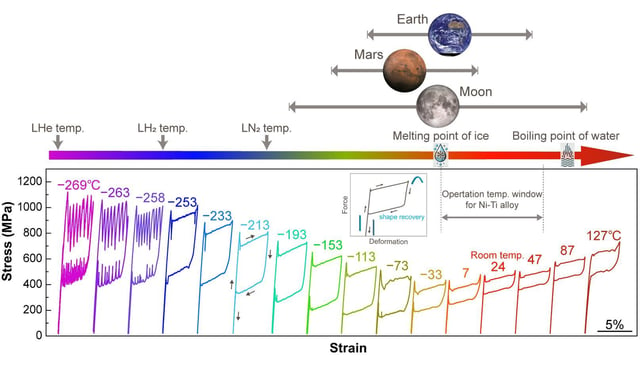

- The titanium-aluminum-chromium (Ti-Al-Cr) alloy exhibits superelasticity across an unprecedented temperature range, from -452°F (-269°C) to 500°F (127°C).

- This material is lightweight, strong, and cost-effective, making it suitable for extreme environments like deep space and deep-sea exploration.

- Potential applications include lunar rover tires that can withstand the Moon's extreme temperature fluctuations and medical devices such as stents and implants.

- The alloy's design uses more abundant materials like aluminum and chromium, reducing production costs and environmental impact compared to traditional alloys.

- Researchers utilized advanced techniques like rational alloy design and precise heat treatment to achieve these superior properties, with findings published in *Nature*.