Overview

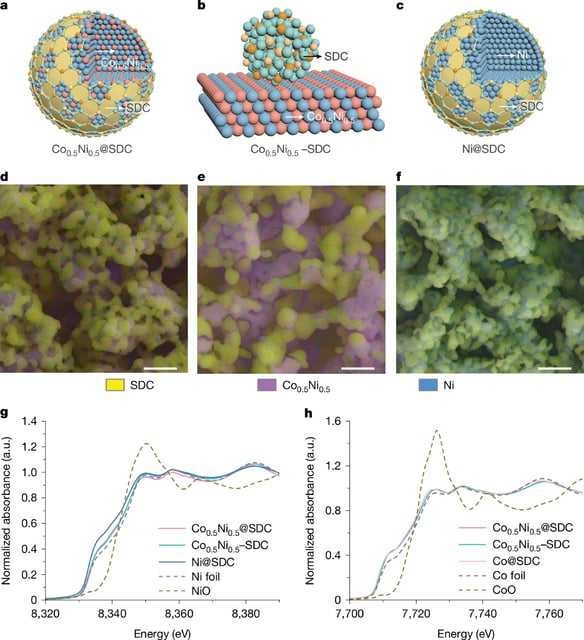

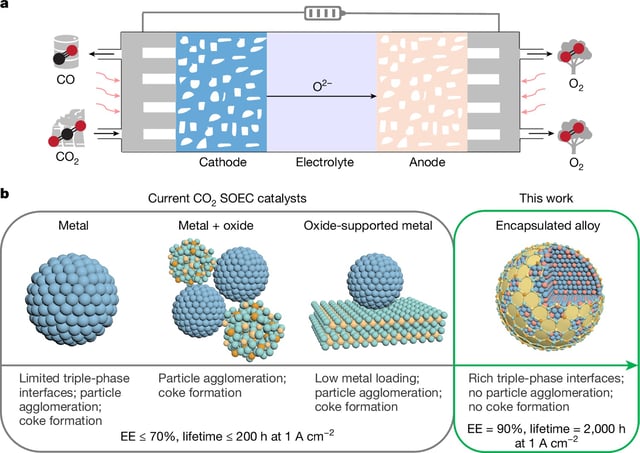

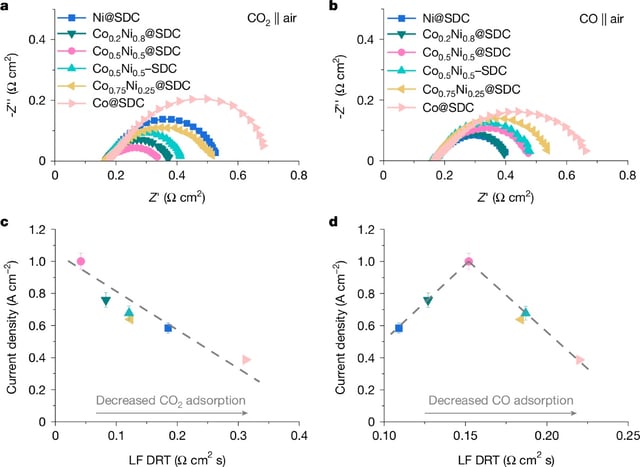

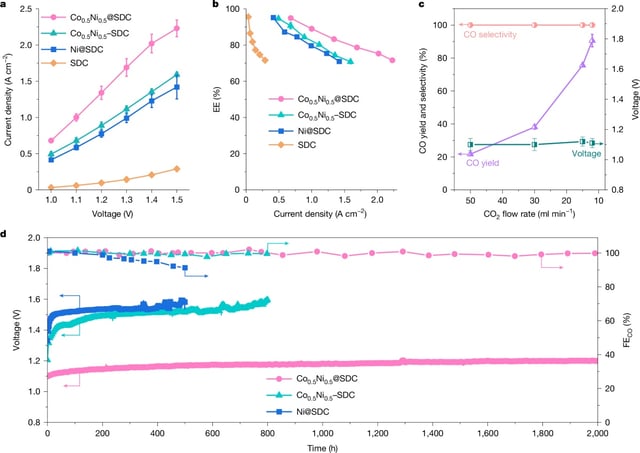

- A cobalt-nickel alloy catalyst encapsulated in a samarium-doped ceria matrix achieves 90% energy efficiency and 100% CO selectivity at 800°C.

- The catalyst demonstrated over 2,000 hours of stable operation, addressing durability challenges in high-temperature CO₂ reduction technologies.

- Preliminary techno-economic analyses suggest the innovation could reduce CO₂ electroreduction costs by 60–80%, enhancing its commercial viability.

- The catalyst was developed using a sol-gel synthesis method, enabling precise control over particle size, composition, and stability under industrial conditions.

- An international patent has been filed to protect the technology, with collaborative contributions from EPFL, ICIQ-CERCA, National Taiwan University, and the Technical University of Denmark.