Overview

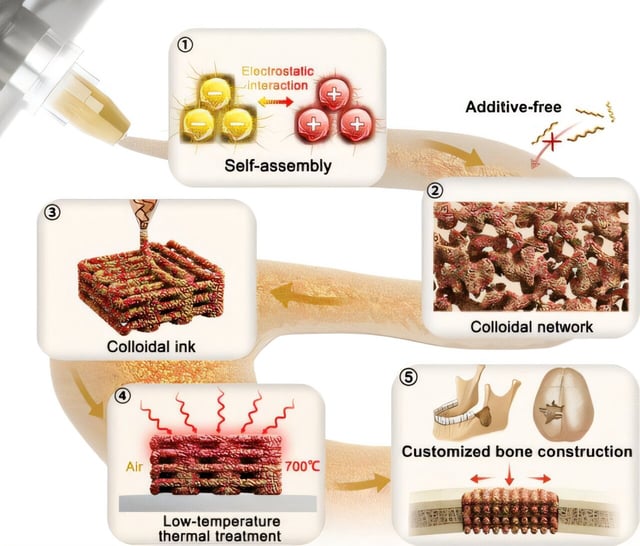

- In ACS Nano, researchers report a bio-active glass formed from oppositely charged silica nanospheres with calcium and phosphate that prints as a self-healing gel and sinters at about 700°C (1,300°F).

- In rabbit skull-repair experiments, the material supported sustained bone cell growth longer than plain silica glass and performed comparably to a commercial dental bone substitute over eight weeks.

- Early bone formation was faster with the commercial product, yet most bone cells present at the study endpoint were found on the new bio-glass scaffold.

- The printed structures retained bioactivity after low-temperature sintering and showed a compressive modulus around 2.3 MPa with improved print fidelity and reprocessability.

- The work is presented as a ‘green,’ potentially lower-cost approach, though translation will require longer-term studies, human biocompatibility and toxicity assessments, and regulatory review.