Overview

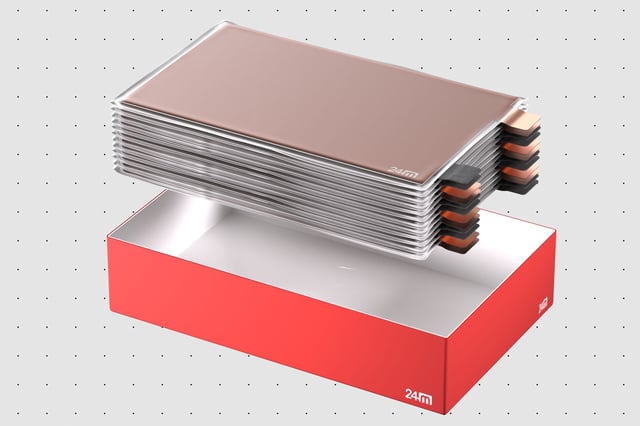

- 24M describes its ETOP architecture as integrating polymer-sealed anode and cathode pairs directly into the pack, removing individual cells and modules to expand active material share to about 80% of pack volume.

- The firm says the design can work across multiple chemistries, including NMC, LFP, NCA and sodium, enabling pack-level energy density gains without enlarging the battery.

- 24M asserts ETOP simplifies manufacturing by eliminating conventional cell fabrication, promising lower costs and only modest capital spending to add the process to existing pack assembly lines.

- The company highlights shape and size flexibility for applications ranging from EVs and energy storage to eVTOL and consumer electronics, and points to potential U.S. cost advantages including eligibility for IRA Section 45X credits.

- According to 24M, first ETOP prototypes are complete and being evaluated, with no independent test data or public automaker adoption announced.